Autonomous monitoring eliminates shrinkage and labor.

Nimbus 9’s Cold Storage Management Solution addresses the second greatest cause of shrinkage: spoilage. Equipment failure is the most common cause of spoilage in restaurants. While restaurant staff is required by local health ordinances to check the temperatures of all freezers and refrigerators multiple times a day it rarely happens.

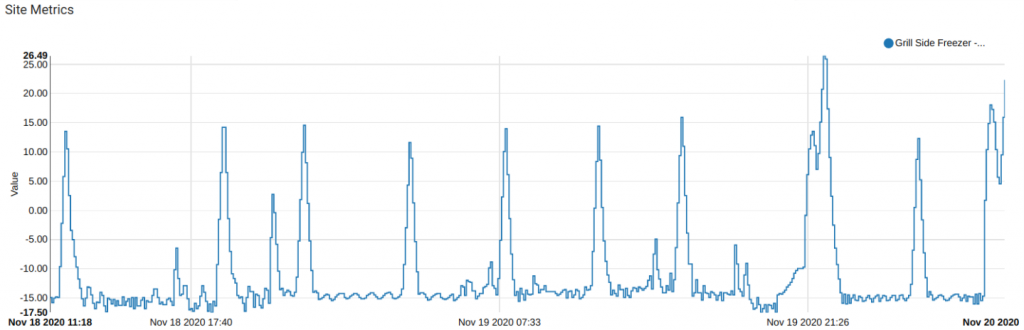

The CSM temperature sensors continuously monitor the temperature of refrigerators and freezers, logging the temperature no less than every 5 minutes. All temperature reads are automatically sent to the CSM platform where they are archived in a time series database.

Nimbus 9’s Cold Storage Monitoring application logs a range of equipment and environmental variables in real-time.

TEMPERATURE

Measuring and controlling of temperature is critical in the food service industry.

Detection Range: -35°C to 65°C (32°F to 113°F)

HUMIDITY

The recommended average relative humidity for indoors is 30 to 50%, when the outside temperature is 20°F or more. Indoor relative humidity above 60% creates an ideal environment for mold and mildew. These contaminants pose a threat to the health of building occupants and cost as well as time consuming remediation for building owners.

Detection Range: 30% to 85% non-condensing. RH +/-5%

DOOR CONTACTS

The use of door contacts deliver significant benefits for cold storage monitoring applications. Door contacts not only provide warnings of refrigerator and freezer doors being left open accidentally but can serve to alert management of product leaving out the back door.

POWER METERING

Power metering of refrigeration systems provides key insights for performance and maintenance. The electrical signatures of refrigeration systems are extremely consistent where defrost cycle intervals track like a Swiss watch. By monitoring electrical signature anomalies failing compressors and other components can be detected and fixed before complete failure.

CARBON DIOXIDE

At room temperature carbon dioxide is a colorless, odorless, faintly acidic-tasting, non-flammable gas. Carbon dioxide at levels that are unusually high indoors may cause occupants to grow drowsy, to get headaches, or to function at lower activity levels. CO2 leaks from cylinders and bulk storage tanks can result in oxygen deprivation and death. The maximum indoor CO2 level considered acceptable is 1000 ppm.

Detection Range: 400 – 5000 ppm

Shrinkage Prevention

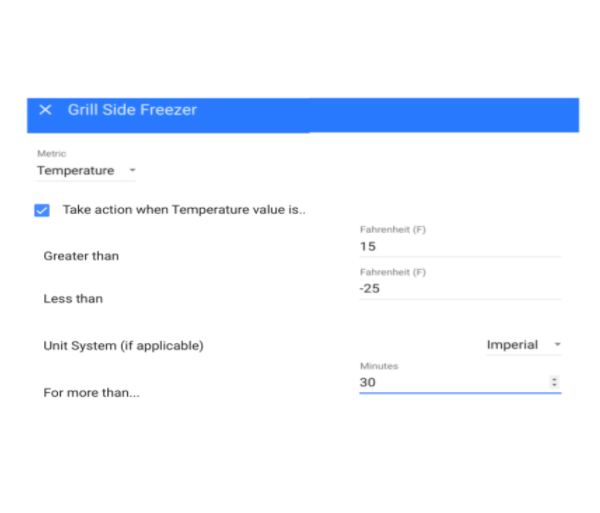

THRESHOLD MONITORING

CSM includes the ability to configure alerts around Min/Max thresholds for each freezer and refrigerator individually. Overtemp and undertemp conditions automatically generate alerts via text or email allowing management time to mitigate risk of spoilage.

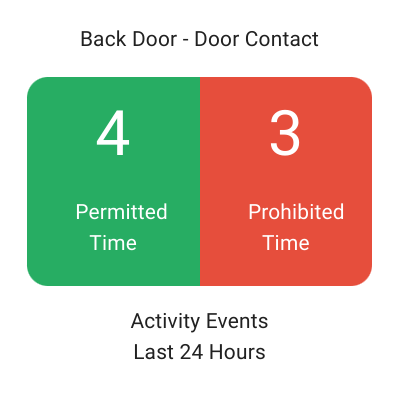

PERMITTED & PROHIBITED TIMES

One of the most effective ways to prevent theft shrinkage is the monitoring of doors through which product can be carried out an establishment.

Like thresholds, CSM allows configuration of alerts when doors are opened. Restaurateurs can customize when the opening of select doors are permitted or prohibited based on their business needs.

CSM uses door contacts to track and log every single time a door is opened or closed. When doors are opened during Prohibited times managers and owners can configure their system to receive real-time text notifications.

CONFIGURABLE ALERTS

Cold Storage Monitoring has the option of a 105 decibel Siren that can be configured to sound when doors are opened during Prohibited Times or are left open too long. These features serve to prevent shrinkage through theft by alerting the Management Team via Siren, Text or both.

ROI Calculator

*assumes 30 seconds per equipment temperature read.

“Before we had CSM managers were spending over 30 minutes a day checking and logging equipment temperatures. Now the system checks and logs everything allowing the managers to manage the business not compliance. Additionally the equipment text alerts have allowed us to address problems immediately.

Lastly having the exact time a door was opened and for how long has saved supervisors many hours of watching video to determine who opened the door. Now supervisors can quickly look up the event on the surveillance system.”

,