CHALLENGE

Head of maintenance Jorge Ruiz was tasked with finding an Indoor Air Quality monitoring solution capable of alerting the management team of any issues that could affect customers and employees alike. This Indoor Air Quality monitoring was required to be installed before the restaurant lobbies were reopened to customers as the restrictions from the Covid 19 lockdowns were lifted.

SOLUTION

After reviewing a few solutions focused exclusively on Indoor Air Quality Monitoring Mr Ruiz selected a more expansive monitoring solution that entailed comprehensive environmental monitoring from Nimbus 9. The Nimbus 9 Environmental Quality Monitoring (EQM) solution was developed for the QSR industry to address their most important operational challenges around customer and employee safety. The EQM application monitors and measures key environmental variables across 2 domains: Indoor Air Quality and Cold Storage Monitoring of temperature sensitive products for Quality Control of perishable goods.

CUSTOMER IMPLEMENTATION

With the aim of total visibility 5Js Enterprises decided to implement Nimbus 9’s monitoring capabilities in all cold storage equipment. The following are the Activity, Temperature and Air Quality sensors that 5Js Enterprises deployed:

Activity Sensors

Back Door Contact

Walk In Freezer Contact

Walk In Refrigerator Contact

Temperature Sensors

Walk In Freezer

Grill Side Freezer

McNugget Freezer

French Fry Freezer

Soda Multiplex

Walk In Refrigerator

Grill Side Refrigerator

Prep Refrigerator

Present Refrigerator

Blended Ice Machine

Air Quality Sensors

Back of House CO2

Beverage Sell CO2

Particulate Matter 2.5

Relative Humidity

Carbon Monoxide

Smoke

Heat

Volatile Organic Compounds (VOCs)

RESULTS

With the aim of total visibility 5Js Enterprises decided to implement Nimbus 9’s monitoring capabilities in all cold storage equipment in their 5 locations. The following are the Activity, Temperature and Air Quality sensors that 5Js Enterprises deployed across their 5 locations:

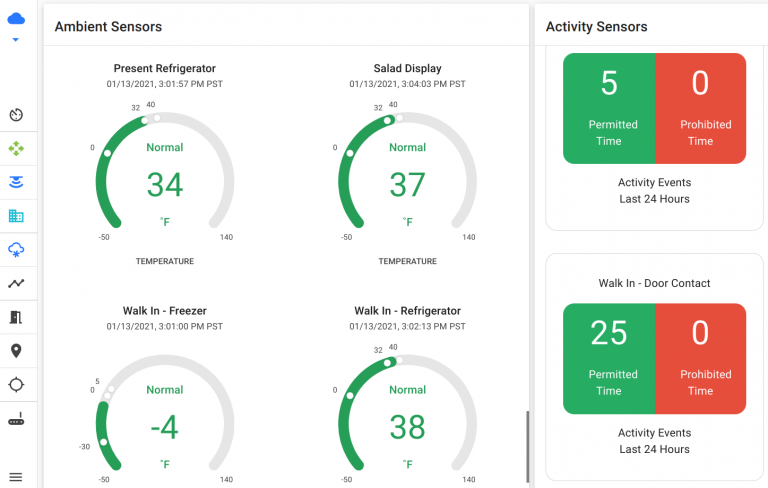

Real Time Dashboards

“For our organization real-time visibility is key. With restaurants up to 65 miles apart and operating in the desert early notification of a problem is critical.

Before I was dependent on managers calling to report a piece of equipment or an area over temp. Since installing the Nimbus 9 system I have actually shown up to look at equipment before the managers even knew there was a problem.The ability to look at equipment performance over time allows me to start diagnosing a problem before I leave the maintenance yard.

If a manager misses a single equipment temperature check it can be up to 8 hours before an issue becomes known. With the Nimbus system I don’t go more than a few minutes without a temperature check and am alerted of any problems right away.

This system has improved my effectiveness and reduced the stress on the maintenance team. Of all the systems capabilities my favorite is the multiplex sensor, I don’t get calls for flat soda anymore.”